What Are You Looking For?

In industrial automation, two common control systems are often compared: the PLC (Programmable Logic Controller) and the Industrial PC (IPC). Both are used to monitor and control machines or processes, but they serve different roles and come with different strengths.

PLC is a rugged, dedicated device designed for reliable control in harsh industrial environments. It is typically used for repetitive tasks such as assembly line control, motor operation, or sensor feedback handling. PLCs are known for their stability, fast response time, and durability. They can operate for years without failure and are resistant to vibration, temperature changes, and electrical noise.

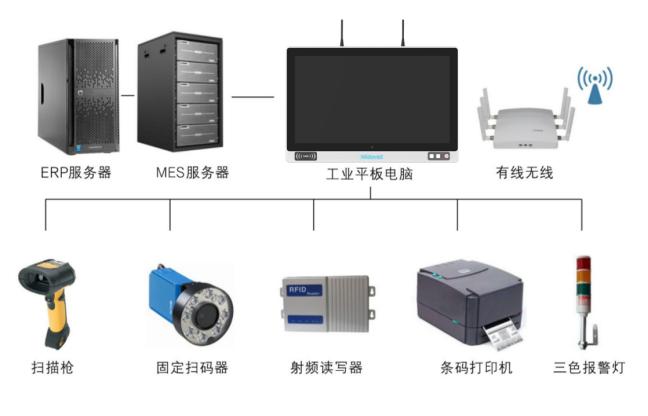

On the other hand, an Industrial PC (also referred to as an IPC or Industrial Panel PC) is a more general-purpose computer designed for industrial settings. It runs operating systems like Windows or Linux and can perform more complex tasks such as data logging, advanced process visualization, or running third-party software. A Low Power Industrial Control Computer or Panel PC for Industrial Applications can combine control functions with user interfaces, making it suitable for more demanding and data-intensive applications.

One of the main differences between a PLC and an Industrial PC is programming and flexibility. PLCs are usually programmed using ladder logic or function blocks, which are specialized for real-time control. They are not meant to run large software programs or multitask. Industrial PCs, however, support modern programming languages, graphics interfaces, and large databases, allowing them to integrate with broader IT systems.

The hardware structure also differs. PLCs are modular, allowing easy replacement or expansion of input/output (I/O) modules. They are compact and often mounted on DIN rails. Industrial PCs are more like traditional computers, but they are built with robust materials and often come in touchscreen panel formats. An Industrial Touchscreen Computer Manufacturer typically designs these systems to withstand dust, moisture, and high usage in control rooms or on production floors.

When it comes to user interface, PLCs usually don’t include one; they rely on HMIs (Human Machine Interfaces) for operator interaction. Many Industrial PCs, especially the Industrial Panel PC With Touch Screen, serve both as the controller and the interface, allowing users to monitor, input commands, and analyze data on one device.

In terms of cost and scalability, PLCs are generally cheaper for simple control tasks and are very reliable for long-term use. Industrial PCs, though more expensive, offer flexibility and power that PLCs can’t match, especially in applications that need real-time data processing, machine vision, or remote access.

Both PLCs and industrial PCs have their place in industrial automation. PLCs are ideal for smaller, specific automation tasks due to their ruggedness, cost-effectiveness, and security. Industrial PCs are better for complex applications requiring high computing and storage capabilities. They offer lower total cost of ownership for complex tasks and are secure with modern cybersecurity measures. Often, a combination of both can balance costs and benefits, depending on the manufacturing process needs.